Did you know that about 400,000 new robots enter the market every year?

Robots are revolutionizing our daily lives. They let manufacturing and production happen quickly and efficiently. The benefits are endless with robot cells.

If you plan on installing a cellular manufacturing plant, then it’s important to understand the functions of each robotic cell. Otherwise, you may end up installing the wrong one, and it won’t be ideal for your company.

We’ve compiled our must-know list so you can get started learning today.

1. What is a Robotic Cell?

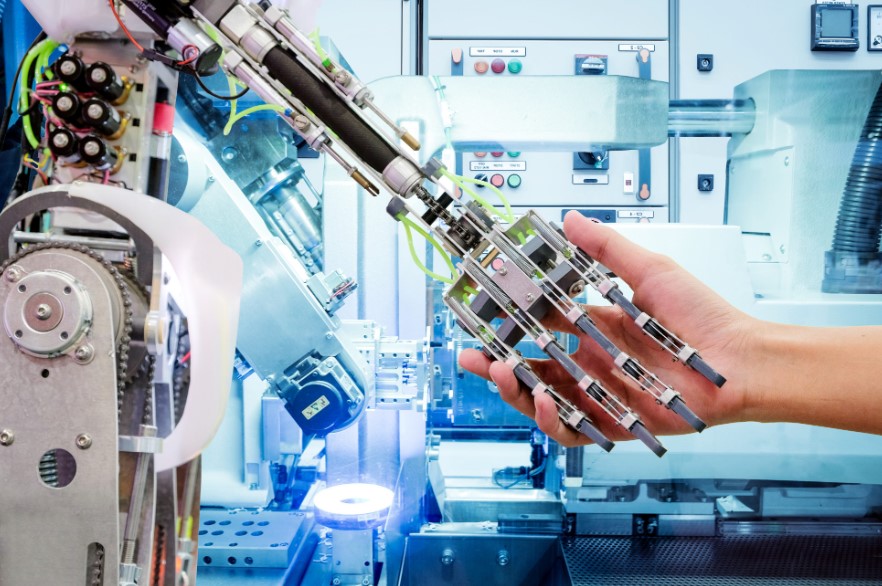

A robotic cell is a collection of robots, computers, and other mechanical components that work together to carry out a specific task. Each cell focuses on a specific production need. This could include robotic welding cells, painting, material handling, assembly, or inspection.

The cell usually consists of several robotic manipulators, conveyors, and vision systems that work together in a defined sequence of processes to complete a task. They’re used in diverse industries such as automotive, aerospace, and medical.

They are capable of precise manufacturing. They can also be used for small-batch and large-scale production.

2. The Benefits

One benefit is efficiency, with software able to guide the robotic arms to carry out specific, high-precision tasks. This can help to reduce the amount of manual labor required and increase production speeds.

Additionally, they can help to reduce errors in manufacturing. They can also reduce the need for more personnel, which can help to control labor costs.

They also reduce operational and maintenance costs. When set up correctly, they need minimal supervision.

Robotic cells can also increase safety. The operator does not have to put themselves in dangerous positions to service them.

Overall, robotic cells provide many benefits to the industry. They’re used in a variety of applications to increase efficiency, accuracy, and safety in the production process. To take advantage of these benefits, check out these compact robotic cells linked here.

3. Managing Safety

Managing safety within a robotic cell requires considering multiple factors. Installation of the robots and surrounding equipment must be done following manufacturer instructions. They should be in accordance with safety standards.

When it comes to safety, providing instructions and retraining the staff dealing with the robots is essential. A safety system for the robotic cell needs to be established. This includes safety guards, emergency stops, and alarms.

Keeping the robotic cell well-maintained will increase safety and performance. This can be done by regularly monitoring the performance of the robots. This also includes the surrounding equipment and taking the necessary steps to fix any issues.

Lastly, creating a detailed risk assessment and procedure plan can guarantee enhanced safety in the cell. Proper training of workers will also make sure that the plan is implemented correctly.

Optimizing Productivity With Robot Cell

Robot cells are highly efficient and cost-effective. They provide various automation options for businesses of all sizes.

Companies looking to reduce costs, increase efficiency, and remain competitive should strongly consider investing in a robotic cell for their operations. If you’re looking to incorporate automated production, contact a robotic consultant today to discuss the possibilities.

Would you like to learn more? Check out our other articles today!